After I finished laying all the track up hill and back down I couldn't wait until I could run my locomotives on the new layout. I don't remember which engine that I did my tests with but it was a diesel. Several days later I was at it again only this time it was with my two year old Rivarossi Cab Forward.

Now comes the bad news, the Cab Forward wouldn't navigate through the Shinohara Crossover. The wheels shorted at the frogs and the drivers derailed. Well to make a very long and sad story short after several weeks of working on the crossover with my Dremel Tool to prevent the derailing there wasn't hardly anything left of the Shinohara turnouts. So I removed what was left and replaced it with a pair of Atlas #6 Custom Line turnouts leaving me with a single crossover and gave up on the double. This made the Cab Forward happy but made me unhappy.

Over the years I tried several commercially manufactured double crossovers without any success. I now have a large fleet of 16 Rivarossi Articulateds and I'm still wanting a double crossover badly. I decided to make my own using Atlas Turnouts and a Atlas 19° crossing. The Rivarossi Locomotives don't have a problem negotiating Atlas Custom Line #6 turnouts. It will require considerable cutting up of all four turnouts and the crossing to mate up to the 2" center to center double tracks.

The following pictures will show my custom modifications to end up with an operational double crossover on my mainline.

The starting point:

The picture below shows the existing single crossover using two Atlas #6 Custom Line Turnouts that I installed 20 years ago.

I laid out the Atlas turnouts on my computer CAD program to make sure it was doable for me to build my own Double Crossover. I made the drawing using an old Atlas code 100 #6 turnout as a go-by. Atlas Customer Service is great, they very quickly confirmed that the new Custom Line #6 Code 83 Turnouts all use the same footprint as my 20 year old code 100 so my drawing will work with the newer series. My drawing is accurate to 1/64" and it confirmed that it is a doable project. If my plan works out the way I designed it on my CAD the crossover won't need any special power switching at the frogs thanks to the Atlas 19° crossing. All of the other manufacturers need frog power switching and some are very complicated too.

The picture above is my CAD drawing that I made of the Atlas 19° crossover to check to see if the project was doable. The drawing is accurate to 1/64". I used the printed drawing as a "paper doll" cutout to match up the crossing to the turnouts. The red and green rails are powered nickle silver, black rails are insulated plastic rails. The thin lines are rails that have been removed. Removing the unwanted ties is a bit tedious and it is very easy to make a mistake but Super Glue to the rescue fixes that.

I posted a full size downloadable PDF drawing on Google Drive of the Atlas #6 turnout that can be used as a template. Click Here

More paper dolls, this drawing is also accurate to 1/64". The ties are not to code 83 specs, they are the larger black code 100 ties from my goby.

The picture above shows the cuts that need to be made to all 4 turnouts to mate with the 19° crossing. Cutting the plastic ties is a challenge here too.

I printed out the drawings actual size on legal size paper then cut them up and used Elmer's Rubber Cement to glue them together to make an actual size drawing.

The picture above shows the cuts that need to be made to all 4 turnouts to mate with the 19° crossing. Cutting the plastic ties is a challenge here too.

I printed out the drawings actual size on legal size paper then cut them up and used Elmer's Rubber Cement to glue them together to make an actual size drawing.

I did real good cutting and splicing the Atlas track, I only screwed up once and that was an easy fix.

I was going to take pictures of my progress along the way but I didn’t figure in how hard the assembly was going to be. Once I had a section put together I didn't want to take it apart again. Getting four rails using Shinohara joiners with different angles to mate up simultaneously is not an easy task.

I now have an Atlas Double Crossover that looks and works extremely good. After my final fix on my error it's very hard to see my screw up and I know where it is.

I used Shinohara #841 rail joiners because of their low profile, they cost a bit more and are harder to install but they really help the esthetics. I soldered the two outside rails at the joiners to maintain alignment.

I used Shinohara #841 rail joiners because of their low profile, they cost a bit more and are harder to install but they really help the esthetics. I soldered the two outside rails at the joiners to maintain alignment.

After I get the crossover installed and working I'll try all my locomotives to make sure they don't have a power pickup problem at the frogs. There are so many unpowered frogs that I might have to switch the power to the turnout frogs with my Tortoise switch machine. Short wheel base locos like my two truck Shays and short tenders on my yard switchers may have problems.

I ran several locomotives towing a string of cars and only had one problem with one of my Cab Forwards, it's pilot wheels were out of tolerance.

Next I will remove it and build up an under table mechanism to operate all four turnouts from a single Tortoise switch machine.

In the past I've had problems using bell cranks as part of the mechanism to move the turnout point rails. Attaching the .020" piano wire to the crank has always been difficult. I may have come up with a fix for that by using a 4-40 nylon screw in the bell crank and drilling a .020" hole through the screw. I tapped the outside hole in each of the nylon bell cranks with a 4-40 tap. The nylon screw works very good holding the .020" piano wire, it gives the wire good strength at the bell crank.

My plan is to use one Tortoise switch machine to throw all 4 turnouts using linkage and bell cranks. The bell cranks that I used are Du-Bro #167.

I'm going to make the under table assembly to drive all 4 turnouts from ¼" Acrylic.

Acrylic Base Plate:

My Acrylic Master Piece is coming along pretty good, no hits no runs no errors.

The Acrylic is 5" wide and 26" long.

I ran several locomotives towing a string of cars and only had one problem with one of my Cab Forwards, it's pilot wheels were out of tolerance.

Next I will remove it and build up an under table mechanism to operate all four turnouts from a single Tortoise switch machine.

In the past I've had problems using bell cranks as part of the mechanism to move the turnout point rails. Attaching the .020" piano wire to the crank has always been difficult. I may have come up with a fix for that by using a 4-40 nylon screw in the bell crank and drilling a .020" hole through the screw. I tapped the outside hole in each of the nylon bell cranks with a 4-40 tap. The nylon screw works very good holding the .020" piano wire, it gives the wire good strength at the bell crank.

My plan is to use one Tortoise switch machine to throw all 4 turnouts using linkage and bell cranks. The bell cranks that I used are Du-Bro #167.

I'm going to make the under table assembly to drive all 4 turnouts from ¼" Acrylic.

Acrylic Base Plate:

My Acrylic Master Piece is coming along pretty good, no hits no runs no errors.

The Acrylic is 5" wide and 26" long.

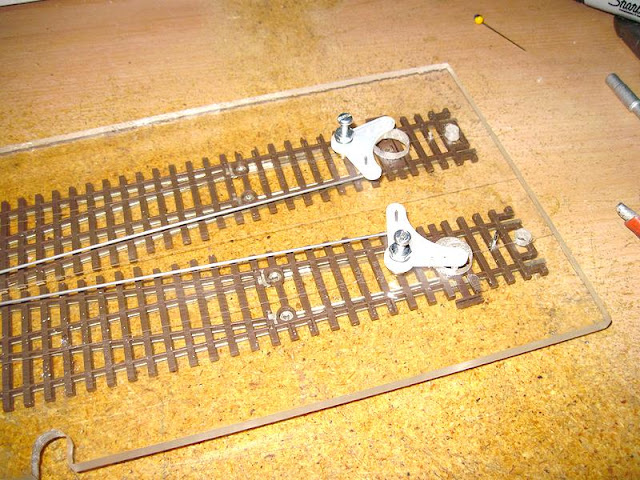

This is a top view with the crossover mounted directly to the ¼" Acrylic. I used my scribe and marked all the hole centers then carefully drilled them.

This is a bottom view with the bell cranks mounted in place. I tapped the Acrylic for the bell crank 4-40 screws. The left side of the Acrylic is 6" longer for mounting the switch machine. The four holes near the center are for wires to the turnout frogs. The U shaped hole on the side is for the wiring to my signal bridge.

The Nylon screws work great, The piano wire fits very snug so I don't think that I will need to glue them in the screws. For checking it out I stuck pins in them and they worked fantastic.

As I was checking the bell crank operation I found a problem with one of the Atlas turnouts. There was a pretty good size chunk of sprue on the inside of the outside point pocket. It kept the point about 1/32" from full closure. That might have been the real problem with my Cab Forward derailing. The Pilot wheels were a bit narrow and needed fixing anyway but I'm glad that I saw that before I had a Conniption Fit later on.

Linkage and Tortoise mounting:

Linkage and Tortoise mounting:

It worked out pretty good, the Tortoise works very smooth and positive. I used Goop Glue to the attach the Tortoise to a metal bracket, then again goop to hold the bracket to the Acrylic. I drilled a ½" hole in the bracket to give me access to the screw holding the piano wire actuator.

This approach didn't work very good.

I measured everything 10 times and still got it wrong! I played around with the linkage between the Tortoise and the bell cranks for a couple of hours before I got it right. I know at least 10 different types of drive systems that won't work.

The smaller diameter .030" piano wire with the hairpin loop worked out very well. The .040" didn't have enough give for the bell cranks to keep the rail points firm in both positions.

The linkage is .040" piano wire. The first linkage between bell cranks worked perfect, I took a measurement and bent it and it was perfect . . . . that's one in a row!!! I used the first link as a goby for the second one so it worked OK too.

It's finished but it tired me out so I'm going to wait until tomorrow to put it in. I was going to call Atlas and talk to an engineer about how to connect to the frogs, I'm afraid to solder to the small contacts for fear of over heating the frog. I checked the contact hole size and then tapped it with a 2mm tap. I'll use 2mm screws with a small lug to connect to the frogs from below. I can cut the screw off flush from above with my Dremel Tool.

I stripped off the 20 year old cork and installed the base plate under the table top.

Next I cut the holes in the new cork then after making sure that everything was lined up properly I glued the cork in place.

After the glue dried I installed the crossover using Shinohara track joiners and put in the track nails. I spent several hours running my diesel locomotives through the crossover forward, backwards and almost sideways. I towed my longest passenger cars through it at a creep and full throttle without any problems at all. Then I went to steam and was very happy that all my steam went well too, fast & slow with plenty of rolling stock behind my Cab Forwards.

Finished:

I am very pleased with the performance of "My Atlas Double Crossover"! I should have made my own years ago. After I play trains for awhile I will get back to making scenery and finish this area. I never finished this section because I always wanted a fully functional double crossover and truly believed that I would have one someday, and that day has finally come!

Finished: